Iron-Framed Boat at Harpers Ferry

by Keith Rocco

Provided by Harpers Ferry National Historic Park, U.S. National Park Service.

Meriwether Lewis (right) and Joseph Perkins, superintendent of the Harpers Ferry armory, inspect the frame of the captain’s collapsible iron boat.

The Lewis and Clark Expedition was based on a geography of hope. Thomas Jefferson, who conceived the great adventure and asked Meriwether Lewis to lead it, believed that the Missouri and Columbia rivers were navigable to their sources and that only a short portage separated their headwaters. Boats were essential to the expedition, and the notion of bringing along a collapsible iron canoe took shape early in the planning. This novel watercraft would be built on an iron frame from materials obtainable from the wilderness—hides for the boat’s skin, pitch for sealing it, and wood and bark for interior components. Whenever needed, the frame could be broken down, carried overland, and reassembled.

Construction

Whether the idea for the iron boat was Lewis’s or Jefferson’s we don’t know, but it was Lewis who worried about the details of its design and fabrication. In March of 1803, Lewis left Washington, D.C., for the federal armory at Harpers Ferry, located on the upper Potomac River in what is now West Virginia. His visit there served two purposes—to outfit the Corps of Discovery with firearms and oversee construction of the canoe’s iron frame.

Lewis spent a month at the armory, longer than he had expected. Following his departure, he stopped in Lancaster, Pennsylvania, for more provisioning. There, on 20 April, he wrote to Jefferson about the iron boat, explaining that his delay at Harpers Ferry had been due to problems converting the concept into a functional watercraft: “my greatest difficulty was the frame of the canoe, which could not be completed without my personal attention to such portion of it as would enable the workmen to understand the design perfectly.”[2]Donald Jackson, ed., Letters of the Lewis and Clark Expedition with Related Documents, 1783-1854, 2 volumes (Urbana: University of Illinois Press, 1978), Vol. 1, p. 39.

In ways that he did not fully explain, working out the boat’s design involved certain “experiments,” including one “to determine its dimentions.” Lewis ordered two sections to be fully assembled—that is, with the iron frame and all the natural materials (hide, wood, and bark) that he expected to gather in the field. Evidently satisfied with the results, Lewis directed the workers to complete the iron frame. Some two months later, when Lewis compiled his expedition inventory, the list included “1 iron frame of Canoe 40 feet long.”[3]Ibid., p. 73.

The iron boat disappears from the record for nearly two years, resurfacing on 13 May 1805. On that day, anticipating the corps’ approach to the Great Falls of the Missouri, Lewis advised his hunters to provide him with elk skins, the intended covering of the assembled frame of his “leather boat.”[4]Gary Moulton, ed., The Journals of the Lewis and Clark Expedition, 13 volumes (Lincoln: University of Nebraska Press, 1984-2001), Vol. 4, p. 149. All quotations or references to journal entries in … Continue reading

The explorers assembled the iron boat in the early summer of 1805 at the Upper Portage Camp, upstream of the Great Falls. There, on 23 June 1805, in a clearing on the banks of the Missouri, under willows protecting them from the Montana sun, Lewis and the men put together the frame. For the next 11 days, they worked on completing the canoe. “We called her the Experiment,” wrote Sergeant Patrick Gass in his journal, “and expect that she will answer our purpose.”[5]Moulton, Vol. 10, p. 110.

Lewis’s Model

Radisson and Groseilliers

by Frederic Remington (1861–1909)

Provided by Buffalo Bill Center of the West, Whitney Gallery of Western Art Collection, gift of Mrs. Karl Funk.

The 17th-century French explorers Radisson and Groseilliers with Indian guides in a canot du maître, which may have served as a model for Lewis’s iron boat. Radisson is the leader and is shown standing. Des Groseillers is sitting beside him.

Unfortunately, Lewis’s journal entries at the Great Falls, like his letter to Jefferson, offer little about the Experiment’s design—only a few tantalizing details about its component parts and even less about its construction.[6]For more on this, see Donald W. Rose, “Captain Lewis’s Iron Boat: ‘The Experiment,’” We Proceeded On, May 1984. But a careful reading of what Lewis wrote, coupled with knowledge about his pre-expedition life as an officer on the Northwest frontier and the construction of bark canoes used by French-Canadian fur traders, can tell us much about the Experiment. The iron boat was not created in a vacuum, and I believe that its design was strongly influenced by the bark canoes of the voyageurs. Consider this excerpt from Lewis’s letter to Jefferson:

Altho’ the weight of the articles employed in the construction of a canoe on this plan, have consistently exceeded the estimat I have previously made, yet they do not weigh more than those which form a bark canoe of equal dimentions, and in my opinion is much preferable to it in many respects; it is much stronger, will carry its burden with equal ease, and greater security; and when the bark and wood are discarded, will be much lighter, and can be transported with more safety and ease.[7]Letter of 20 April 1803, to Jefferson. Jackson, p. 40.

Here and elsewhere in the letter, as well as in his journals, Lewis refers to the iron boat as a “canoe,” and his wording suggests that it was modeled on “a bark canoe of equal dimentions.”[8]See also the reference in his inventory. Jackson, p. 73.

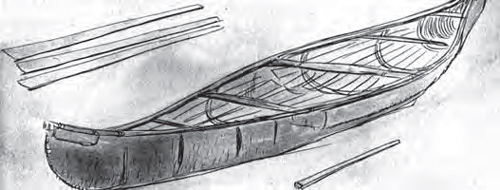

The bark canoes built by Indians in eastern Canada and adopted by European fur traders had long been the most efficient means of traversing the American wilderness. They carried men and supplies over the vast network of waterways penetrating the continent.[9]For more on the indispensable use of the canoe in the exploration of North America, see Peter C. Newman, Caesars of the Wilderness (Ontario: Viking, 1987); and David Lavender, Winner Take All (New … Continue reading Lewis had firsthand knowledge of these versatile watercraft. As an army officer he had been stationed at Fort Detroit, a post situated on one of the main fur-trade routes. The Detroit area was also a hub of canoe manufacturing.[10]Richard Dillon, Meriwether Lewis: A Biography (New York: Coward-McCann, 1965), p. 25. Kenneth G. Roberts and Phillip Shackelton, The Canoe (Toronto: Macmillan of Canada, 1983), p. 198.

At the Upper Portage Camp, when assembly of the Experiment was nearly complete, Lewis recorded that the frame exceeded 36 feet.[11]Moulton, Vol. 4, p. 356. Only one bark canoe reached this length, and the similarity can hardly be a coincidence. The Experiment’s model was the canot du maître, the fur-trade canoe used for crossing the Great Lakes. These canoes were 36 or more feet long, 5 or 6 feet wide at the beam, and 30 inches deep at midships. The Experiment’s width and depth were 4 1/2 feet and 26 inches, respectively—smaller than those of the typical canot du maître but consistent with the size of these vessels.[12]Edwin Tappen Adney and Howard I. Chapelle, The Bark Canoes and Skin Boats of North America (Washington, D.C.: Smithsonian Institution Press, 1983), p. 138. (A narrower canoe meant a faster canoe, although it sacrificed some load-carrying capacity.)

The process of building bark canoes casts light on the design and construction of the Experiment.

Building Bark Canoes

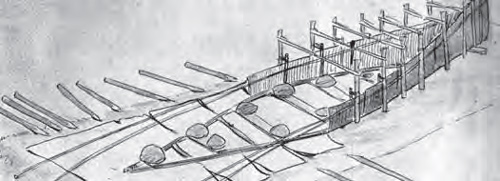

Steps in Building a Bark Canoe

The frame (inwales and thwarts) is assembled and laid upon the building bed, a clearing on the ground. Stakes—used later on to support the sides during their construction — are driven into the bed.

The stakes are removed, and the bark is laid down with the frame on top of it in the same position as before. Rocks weight down the frame.

In a process that starts at one end and works to the other, the bark is folded and held in place by the stakes, which are reinserted as the work progresses, and by inboard battens tied to the stakes. Horizontal strips are inserted to help shape the sides. These are later removed.

The outwales have been added, completing the gunwales. The bark is pressed between the outwales and inwales and the entire assemblage has been lashed tightly. Cedar sheathing or planking, held in place by widely spaced temporary ribs, has been added. In the stem, work has started on tapping into place the closely spaced permanent ribs.[13]Illustrations adapted from Edwin Tappen Adney, The Bark Canoes and Skin Boats of North America (1964); text from Adney and John A. McPhee, The Survival of the Bark Canoe (1975).

The bark canoe is an exquisite feat of engineering. Samuel de Champlain, one of the early explorers of the St. Lawrence River and interior Canada, watched in amazement as a canoe propelled by only two paddlers—one of them a woman—easily passed his fully manned long-boat.[14]Samuel de Champlain, Voyages in New France, as quoted in Roberts and Shackelton, p. 171. The French-Canadian fur traders refined the longer canoe into the canot du maître and established a canoe “factory” at Trois Rivières, on the St. Lawrence River. When the British displaced the French, they too depended upon the canot du maître and continued the factory’s operation, employing both French-Canadian and native craftsmen.[15]Adney and Chapelle, p. 13; Roberts and Shackelton, p. 197.

Regardless of length, every bark canoe had the same basic features—most notably its covering, the bark of the paper birch, Betula papyrifera. Birch bark was waterproof, flexible, and durable. Minor damage such as splits and tears could be easily repaired in the field.[16]In areas where birch did not grow, natives covered their canoes with the bark of elm, spruce, hickory, or basswood—but these were less durable substitutes. Some builders—notably the Inuit and … Continue reading

In thinking about the construction of a bark canoe (and also Lewis’s iron boat, which followed many of the same principles) one should keep in mind that it was built from the outside in, starting with the bark and frame. Only after these were in place was the interior completed.[17]The following description of bark-canoe construction is based on Roberts and Shackelton, pp. 156-163; Adney and Chapelle, pp. 145-150; and John McPhee, The Survival of the Bark Canoe (New York: … Continue reading Following is a highly simplified explanation of how bark canoes were constructed. (See the sidebar on page 29 for a more thorough description.)

Before starting, builders gathered all necessary materials. Cylindrical lengths of bark were cut from birch trees. (On rare occasions they found a tree wide and tall enough to yield a single piece sufficient to cover the entire canoe, but most of the time they resorted to sewing several smaller pieces together.) Wood from pliable white cedar or black spruce was cut to different lengths, widths, and thicknesses for various components: inwales and outwales, which together form the gunwales (the rail-like edge capping the boat’s sides), stempieces (the curved extensions of the keel that give a canoe its graceful, distinctive shape), ribs, and sheathing (the lining placed between the ribs and the bark).

Wood for thwarts (crosswise bracing bars) was cut from hard maple or ash. Thin spruce roots made the twine-like strands, called wattape, used for lashing and sewing.[18]Eric Morse, Fur Trade Canoe Routes of Canada, Then and Now (Toronto: University of Toronto Press, 1969), p. 23. Moulton (Vol. 4, p. 346, fn. 3) states that Lewis also used the word … Continue reading Pitch, the key ingredient in the sealant used on seams and lash holes, was extracted from spruce or pine and stored in baskets.

The builders placed two of the cedar strips side by side, then tied them at each end with wattape. These formed the inwales. They spread the inwales on the ground and notched them to accept the thwarts. Cut and shaped, the thwarts were then inserted into the notches and lashed to the inwales, forming the canoe’s frame.

After soaking to make it pliable, the bark was placed upon a flat piece of ground. The frame, which also served as a template for the canoe, was laid upon the bark. Working from one end to the other, the builders cut the bark in sections and folded it upward to create the sides. Then they lifted the frame and secured the sides to it by sandwiching the bark between the inwale and outwale.

The builders could now begin work on the interior structure. They started with the stempieces, which were inserted at both ends of the canoe and lashed to the bark. Next, the cedar planks, or sheathing, were secured to the inside of the canoe. The builders laid the planks adjacent to each other and flush against the bark, shaping and trimming them for a tight, smooth fit. Finally, the ribs, which had been soaked and bent into a U shape, were inserted and tapped in place with a mallet. The ribs ran from stem to stem and were positioned about three inches apart.

Seats were planks suspended from the gunwales by leather strips or wattape. The number of seats depended upon the number of paddlers. The crew of a typical canot du maître averaged 8 to 10 men, but as many as 17 labored on the very biggest canoes, which plied Lake Superior. Generally, two paddlers shared a seat.

The last, critical step was applying the sealer to the bark’s seams and its sewing and lashing holes. The sealer waterproofed the seams and holes. (The birch bark was naturally waterproof.) Before it was applied, the pitch was heated to soften it, and tallow and charcoal were added to make a gooey, tarlike substance. The builders worked the sealer into every place where the canoe might leak.

By comparing bark-canoe construction with Lewis’s description of assembling the Experiment at the Upper Portage Camp and details in his letter to Jefferson, we can begin to unravel many of the secrets of what the captain referred to as his “favorite boat.”[19]Moulton, Vol. 4, p. 369 (entry for July 9, 1805).

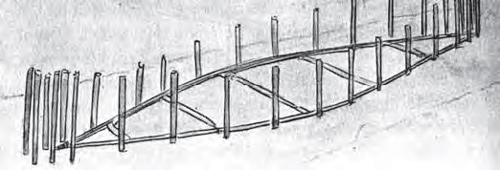

Eight Discrete Sections

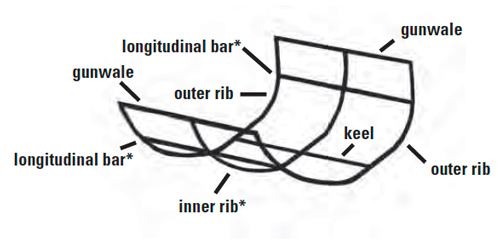

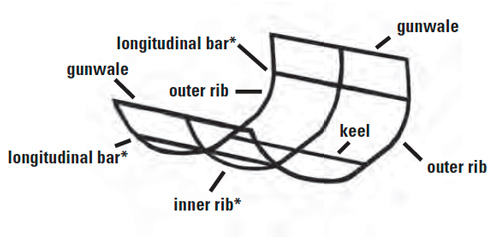

Lewis’s genius reduced the basic canoe frame to eight discrete sections and substituted iron for wood. Each section of the iron frame constituted a subassembly of the whole and consisted of ribs, longitudinal pieces, and other parts, so it could be carried in a collapsed state and put together when needed. Additional components—wooden bars and stays, bark lining, a covering of sewn hides, and sealant—could be made on the spot from materials that Lewis assumed would be readily available in the field.

Despite this simplification, the design and execution of the iron frame was anything but easy. Unaccustomed to casting anything so novel, the Harpers Ferry ironworkers demanded Lewis’s hands-on guidance. As previously noted, in his letter of 20 April 1803, from the federal armory, Lewis explained to Jefferson that his biggest challenged was getting “the workmen to understand the design perfectly.”[20]Jackson, p. 39.

Also as noted, Lewis’s “experiment” involved the assembly of two sections—”the one curved, or in the shape necessary for the stem and stern, and the other simicilindrical, or in the form of those sections which constitute the body of the canoe.”[21]Ibid. Lewis uses “stern” to refer to the after end of the canoe. A canoe, of course, is symmetrical, so that either end can be the stem (fore end, or bow) or stern, depending on the … Continue reading

Center Sections

The two types of sections had distinctly different design elements. The semi-cylindrical center sections formed the main body of the canoe. In his letter to Jefferson, Lewis listed their dimensions:

| Simicilindrical Section | F[eet] | I[inches] |

|---|---|---|

| Length of Keel | 4 | 6 |

| Ditto beam | 4 | 10 |

| Debth of Hole | 2 | 2 |

| Note—The curve of the body of the Canoe was formed by a suspended cord.[22]Jackson, p. 39. | ||

Lewis doesn’t describe the components of a center section, but we can make some hypotheses about them based in part on the above data. The “Keel” would have been an iron bar running fore and aft and joined to the bottom of the section’s two U-shaped outer ribs. I say “outer” ribs because there were almost certainly one or two interior ribs spaced along the keel as well.

Although Lewis doesn’t list them, each section must also have had gunwale bars. One can also assume (though again they aren’t mentioned) that a section had longitudinal bars—perhaps two or three on each side—running fore-and-aft to give shape to the section and augment its structural integrity; these would have been structurally equivalent to the horizontal sheathing in a bark canoe.

The number of longitudinal bars and ribs would have depended to some degree on the thickness of the iron— yet another unknown. Lewis at least is clear about the overall dimension of a center section: Length, 4 feet 6 inches; width (beam), 4 feet 10 inches; and depth of the whole (“hole”), 2 feet 2 inches.

Curved Sections

The two curved sections formed the stempieces (the bow and stern). Given their curves and tapers, fabricating these sections must have posed special challenges to the iron-workers. Lewis lists some, but not all, of their dimensions:

| Curved Section. | F[eet] | I[nches] |

|---|---|---|

| Length of Keel from junction of section to commencement of curve | 1 | 2 |

| Length of curve | 4 | 5 |

| Width of broad end | 4 | 10 |

| Debth of Do. Do. | 2 | 2 |

“Keel” refers to the flat part of the bottom bar, and “curve” to the part that rose from the end of the flat part to its junction with the gunwales. The “broad” or open end was defined by the rib that attached to the adjacent center section. “Do. Do.” means “ditto” and refers to the depth of the broad end. Because it was the point of connection, the width and depth of the broad end of the curved sections and the connecting center sections were identical—4 feet 10 inches and 2 feet 2 inches. We know that the stem sections, like the center sections, must have had gunwales, as well as an unknown number of longitudinal bars and ribs.

The total horizontal length of the curved section isn’t stated but can be deduced. Lewis tells us that the “length of curve,” meaning the length of the curved part of the bottom bar, was 4 feet 5 inches. We know this part rose a vertical distance of 2 feet 2 inches. A gently engineered curve would yield a horizontal length of 3 feet 7 inches, which added to the keel’s horizontal length of 1 foot 2 inches gives a total horizontal length of 4 feet 9 inches. This measurement is consistent with the final assembled length of the Experiment.

Length, Weight and Capacity

Lewis doesn’t tell us the number of center sections, but in his journal entry of 3 July 1805, Private Joseph Whitehouse informs us that the boat had eight sections in all.[23]Moulton, Vol. 11, p. 217. Because there were two stem sections, the number of center sections must have totaled six.[24]This number can also be confirmed by the section lengths recorded by Lewis. Multiplying 4 feet 6 inches (the length of one center section) by six yields 27 feet, which subtracted from 36 feet 4 1/2 … Continue reading

The final assembled length of 36 feet 4 1/2 inches does not match Lewis’s 1803 inventory of a 40-foot iron canoe.[25]Jackson, p. 73. When he recorded his field measurement two years later at the Upper Portage Camp, it was probably the first time all eight sections were actually assembled. Perhaps Lewis got his arithmetic wrong or “rounded up” by several feet. Or (more likely) there was a good deal of tolerance in the engineering specifications.

Knowing the number of sections, the Experiment’s total weight can be calculated from the following data found in Lewis’s letter to Jefferson.[26]Ibid., p. 39.

| Curved Section | lbs. | Simicilindrical Section | |

| Iron | 22 | Iron | 22 |

| Hide | 25 | Hide | 30 |

| Wood | 10 | Wood | 12 |

| Bark | 21 | Bark | 25 |

| Total | 78 | Total | 89 |

| Burthen of 850 lbs. | Burthen of 920 lbs. |

| Iron and Hide of Curved Section | 47 | |

| Iron and Hide of Simicilindrical Do. | 52 | 99 lbs. |

| Burthen of Curved Section | 850 | |

| Do. Do. Simicilindrical | 920 | 1,770 lbs |

The iron in each section weighed 22 pounds, so the iron of the two stem, or curved, sections weighed 44 pounds, while the iron in the six center, or semicylindrical, sections weighed 132 pounds. The total weight of the iron frame—176 pounds—was a reasonable burden to carry up the Missouri.[27]Compare this result with the weight assigned to the Experiment in other secondary sources. On page 31 of Lewis and Clark: Historic Places Associated with Their Transcontinental Exploration … Continue reading

The final assembled weight—the iron frame plus other components—can now be estimated. The iron in each curved section weighed 22 pounds, the hides 25 pounds, the wood 10 pounds, and the bark 21 pounds. The total weight for a single curved section was 78 pounds (22 + 25 + 10 +21), so the two curved sections when fully assembled weighed 156 pounds.

In each of the six semicylindrical sections the iron weighed 22 pounds, the hides 30 pounds, the wood 12 pounds, and the bark 25 pounds, for a total of 89 pounds. The combined weight of the six semicylindrical sections was 534 pounds. Adding the 156 pounds of the two curved sections yields a total weight for the fully assembled canoe of 690 pounds. Lewis believed the “articles employed in the construction of a canoe on this plan … do not weigh more than those which form a bark canoe of equal dimentions.”[28]Jackson, p. 40. He also boasted that the completed Experiment was lighter “than any vessel of her size that I ever saw.”[29]Moulton, Vol. 4, p. 356. The actual field materials assembled at the Upper Portage Camp were probably heavier than those Lewis used in making his estimates at Harpers Ferry. In fact, a 36-foot bark canoe weighed between 500 and 600 pounds.[30]See Roberts and Shackelton, p. 200. Weight would vary based on length and width.

The fur-trade canoe had a hauling capacity, or burden (spelled “burthen” by Lewis), of 8,000 pounds.[31]Ibid., p. 204. At the Upper Portage Camp, Lewis confidently stated that the Experiment was “strong and will carry at least 8,000 pounds with her suit of hands”—an estimate probably based upon his knowledge of the fur-trade canoe.

Lewis had initially calculated the canoe’s burden as part of his Harpers Ferry experiments. A curved section’s “burthen” tested at 850 pounds, so the two curved sections had a combined capacity of 1,700 pounds. A semi-cylindrical section tested at 920 pounds, so the six sections could handle 5,520 pounds, yielding a total capacity of 7,220 pounds.[32]Jackson, pp. 39-40. Both Appleman (p. 31) and Dillon (p. 38) mistake the Harpers Ferry calculation for the total burden of the canoe, asserting that the Experiment could carry only 1,770 pounds. … Continue reading Lewis was reasonably certain that his canoe could haul a greater load. In his letter to Jefferson, he noted that when the sections “were united they appeared to acquire an additional strength and firmness” that would enable the canoe to carry an additional 600 to 1,200 pounds.[33]Lewis’s exact wording is, “I am confident that in cases of emergency they would be competent to 150 lbs.” If each of the eight sections could carry 150 additional pounds, it would … Continue reading

He confidently declared his iron-frame canoe to be stronger than a bark canoe and also lighter to carry: Whenever the boat required portaging, Lewis asserted, its bark and wood components could be discarded, “as those articles are readily obtained for the purposes of this canoe, at all seasons of the year, and in every quarter of the country, which is tolerably furnished with forest trees.”

Assembly

Leading a small advance party, Lewis came upon the Great Falls on 13 June 1805. The rest of the expedition arrived several days later in six dugout canoes and the white pirogue (the red pirogue having been cached downstream at the mouth of the Marias).[34]A pirogue is a wooden boat, often in the shape of a canoe. Lewis used the terms pirogue and canoe interchangeably when referring to the expedition’s two pirogues. (Moulton, Vol. 2, p. 71, fn. 1.) … Continue reading The explorers set up camps below and above the falls and began the long and difficult job of portaging their tons of supplies and equipment.

The captains decided to leave the white pirogue at the Lower Portage Camp and replace it with the iron boat, whose frame components would be hauled overland for assembly at the Upper Portage Camp. On 18 June 1805, recorded Lewis, they examined the frame “and found all the parts complete except for one screw.”[35]The “screws” used for assembling the frame had threads that matched the grooved holes drilled into the frame. Whitehouse is quite clear about this when he states that the iron boat had … Continue reading John Shields, the corps’s inventive blacksmith, easily replaced it. The next day, they cleaned the frame components of rust and greased them to protect against further oxidation.

On 21 June 1805, Lewis assigned Gass, Shields, and Joseph Field to carry the iron frame to the Upper Portage Camp. In his journal entry for that day, he noted “several difficulties in preparing the leather boat which are the want of convenient and proper timber; bark; skins and above all that of pitch to pay [seal] her seams, a deficiency that I really know not how to surmount.”

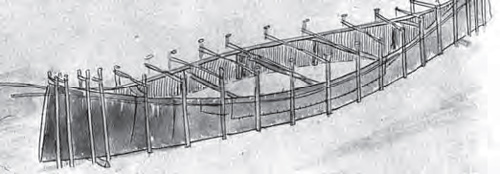

At the upper camp he selected a willow-shaded site for assembling the boat. The four men cleared away some brush and quickly put together the sections. Lewis recorded the frame’s dimensions— length, 36 feet 4 1/2 inches, width 4 feet 10 inches, depth 26 inches.[36]Ibid., p. 330. Gass’s entry of 23 June 1805 (Moulton, Vol. 10, p. 105) records the same measurements. Assembling the frame at this point appears to have been done for the purpose of obtaining the measurements needed for building the rest of the boat from natural materials, and the sections were subsequently disassembled so they could be worked on individually.[37]This can be inferred from Lewis’s journal entry for July 2, eight days after the measurements were taken: “myself and all other hands engaged in putting the boat together which we … Continue reading

Wood Parts

Lewis’s journal entries are short on specifics about the iron boat’s wooden components. For example, he writes about “horizontal bars” and “cross stays” but fails to describe their appearance or function.

Once again, a knowledge of bark-canoe construction sheds light. The ribs of a bark canoe were spaced vertically from stem to stem roughly three inches apart, providing a dense framework for supporting the sheathing and bark. In the case of the Experiment we can be certain that, given the lightness of its iron frame, it had many fewer ribs than a bark canoe, and with wide gaps between them.

The horizontal iron elements probably consisted of gunwale (top) bars, keel (bottom) bars, and no more than three longitudinal bars on each side of the canoe, so there would have been significant gaps between these elements, too. The wooden horizontal bars were laid along the iron frame and provided additional structure to support the hide covering and bark lining.[38]On 27 June 1805, Lewis recorded that “Shields and Gass continued the operation of shaving and fiting the horizontall bars of wood in the sections of the boat.” Patrick Gass—the … Continue reading The wooden cross stays spanned the width of the canoe and functioned as thwarts.[39]Originally, Lewis probably planned to add only a few wooden horizontal bars because he intended to use large sheets of bark as the primary support, or lining, for the skin covering. In the … Continue reading

From the start there were problems gathering and finishing the natural materials. On 24 June 1805, Lewis recorded that Gass and Shields had “great difficulty in getting streight or even tolerably streight sticks of 4 1/2 feet long” for use as wooden horizontal bars. The search extended for several days, and once acquired, the timber proved “so crooked and indifferent that they make but little progress.”[40]Entry for 27 June 1805. The men shaved and notched the sticks on the inner side so they could be fitted to lie flat against the ribs, while the outer side was shaved to present a flat surface for the bark lining and skin.[41]On p. 41 of The Way to the Western Sea, Lavender states that a lattice of sticks supported the covering. If by “lattice” he meant the classical use of wood sticks laid over each other, … Continue reading

Bark, Waystrips and Covering

The bark confounded Lewis even more. He intended to “line” or “bind” the canoe with bark that would lie between the frame and the hide covering. This was equivalent to the sheathing in a bark canoe. The men spent several days hunting for suitable material, for nothing in the Montana prairie resembled birch. Lewis noted on 28 June 1805, “I sent [Gass and Shields] in surch of willow bark, a sufficient supply of which they now obtained to bind the boat.”[42]Moulton, Vol. 4, p. 337. Earlier journal entries note that Gass and Shields searched for bark as well as timber. See, for example, Moulton, Vol. 4, pp. 331 and 333. Lewis recorded that on 26 June … Continue reading Once collected and cut, the bark had to be soaked to make it sufficiently flexible to conform to the shape of the hull.[43]In his entry for 30 June 1805, Lewis refers to this soaking process as necessary to “toughen the bark.” The context suggests that his purpose was to render the bark flexible so it could … Continue reading

Before the boat could be lined with bark, the wooden horizontal bars and cross stays had to be lashed to the iron frame. This would be accomplished with what Lewis called “way strips,” made from thin bark stripped from willow branches and similar to the wattape used by the builders of bark canoes.[44]Lewis, July 1: “Gas[s] I set at work to make the way strips out of some willow limbs which tho’ indifferent were the best which could be obtained.” Moulton suggests that “way … Continue reading

The outer covering would be made of elk skins, which Lewis had been collecting since the expedition’s departure from the Knife River Villages three months earlier.[45]Moulton, Vol. 4, p.149. Some of these he had to abandon because of rot.[46]Ibid., p. 261. Lewis sent George Drouillard, George Shannon, and Reuben Field to shoot elk for fresh skins to replace those lost.

The skins had to be sewn to make a covering large enough to fit the frame. Lewis designated Robert Frazer and Joseph Whitehouse to sew them together. The corps carried an ample supply of needles, and way strips served as lashing.[47]Jackson, pp. 71 and 72. Lewis’s inventory list included six saddler’s needles plus 24 gross of needles for Indian presents. Lewis preferred elk skins, believing them to be tougher and more durable than buffalo hides, but when the hunters failed to shoot enough elk he sent the men in search of buffalo. Preparing the hides was a tedious job that took a week and involved stripping them of hair.

The men shaved off the fine, hollow elk hair and with torches burned off the coarser buffalo hair.[48]Moulton, Vol. 4, p. 338. To make them easier to sew, the shorn and singed hides were then soaked in the river overnight. Covering all eight sections of the iron boat took a total of 28 elk hides and four buffalo hides.[49]Lewis makes it reasonably clear that the sewing of the hides was done on a section-by-section basis. See Moulton, Vol. 4, pp. 344, 349.

By the end of June, Lewis had nearly all he needed to complete his canoe: the assembled sections of the iron frame, the wood necessary to fill in the structure and brace it, the hides to cover the frame, and the bark to line the space between the frame and the hides.

Final assembly took more than a week and probably proceeded along the lines described below. (Most of this is based on documentary evidence from the journals, but some of it is conjectural, based on the principles of bark-canoe construction.) They began on July 1, when Lewis ordered Frazer and Whitehouse to sew the hides to each of the eight discrete sections, a task they completed by that evening. The next morning, Lewis and his team connected the sections, a job that took three hours. It would take another three days to complete the assembly, which involved inserting the wooden cross braces, lashing the wooden horizontal bars to the iron ribs, and inserting the bark pieces between the frame and the hide covering. Each section’s covering was sewn to the adjacent covering, creating a single composite skin. To thoroughly dry the skin in preparation for sealing the seams and stitch holes, the canoe was placed upside down on scaffolding and low fires were kindled underneath it.[50]Ibid., pp. 349, 351, and 363. In his journal entry for 21 June 1805, Whitehouse states that the iron boat “had screws to fasten the hides or skins that covered the bottom & sides.” … Continue reading

“Paying”

Lewis’s journal entries reflect a sense of pride in his creation. On July 5, he wrote, “the boat in every other rispect completely answers my most sanguine expectation; she is not yet dry and eight men can carry her with the greatest ease; she is strong and will carry at least 8,000 lbs. with her suit of hands; her form is as complete as I could wish it.”

His enthusiasm, however, was tempered by a note of caution: “the stitches begin to gape very much since she has begun to dry.” Lewis was right to worry, for sealing, or “paying,” the stitched seams was essential to the Experiment’s watertight integrity. Lewis planned to use tar made from pitch for the job and had wrongly assumed they would find ample pine or spruce growing at the Great Falls. Instead, he had to settle for pine logs he found “among the drift wood near this place, from which, I hope, to obtain as much pitch as will answer to pay the seams of the boat.”[51]Entry of 24 June 1805. Moulton, Vol. 4, p. 330. Clark on 3 July 1805 noted that the men were “burning tar of the drift pine.”

On 1 July 1805, he ordered Shields and Joseph Field to collect as much wood as they could and “prepare a pit to make tar.” Alas, after 24 hours, “our tar-kiln” produced an abundance of charcoal but no tar, and Lewis worried that it “will not yeald any.” His concerns proved well founded: by Independence Day the kiln had failed to produce even a drop.

As an alternative sealer he opted for a mixture of tallow, charcoal, and beeswax. A similar concoction had been successfully used to fill cracks in the dugout canoes.[52]Lewis, 21 June: “I readily perceive several difficulties in preparing the leather boat . . . above all that of pitch to pay her seams, a deficiency that I really know not how to surmount unless … Continue reading (The fact that two of these three ingredients—tallow and charcoal—were also components of the sealant used on bark canoes is further evidence that Lewis had at least a theoretical knowledge of bark-canoe construction.) Though a bark canoe would have been pitched solely at the seams and holes, Lewis on 8 July 1805 ordered the men to cover the entire surface with this composition, which “gives her hull the appearance of being formed of one solid piece.” After the first coat cooled, “I gave her a second which I think has made it sufficiently thick.”

Tuesday, 9 July 1805, was the day of reckoning. By now, the entire corps was assembled at the Upper Portage Camp, along with all the supplies and six dugout canoes portaged from below the Great Falls. The plan was to load all the boats and proceed upriver.

Late that morning, Lewis and his men lifted the Experiment off the scaffold and placed it in the Missouri.[53]Gass states that the boat was launched in the “forenoon.” (Moulton, Vol. 10, p. 110.) The captain then ordered the seats to be lashed in place. We can assume that, like the canot du maître and other bark boats of the Canadian fur trade, the seats were wooden planks suspended from the gunwales with leather or willow strips. Lewis was pleased and doubtless relieved to see that the boat “lay like a perfect cork upon the water.” The more objective Gass noted that the vessel “rides very light but leaks some”—a telling detail also mentioned by Whitehouse but absent from Lewis’s journal.[54]Moulton, Vol. 4, p. 368; Vol. 10, p. 110; and Vol. 11, p. 221. Whitehouse recorded that “the iron boat leaked so much, that we did not put any load into her.” (Moulton, Vol. 11, p. 222.)

Supplies were loaded aboard the dugouts but, presumably because of concerns about leakage, not the iron boat. Then, in the words of Lewis, a violent windstorm “commenced and blew so hard that we were obliged to unload the canoes.” The wind “continued violent untill late in the evening.” When at last it abated and they returned to the river, Lewis to his chagrin saw that the iron boat had filled with water. Hauling it ashore, they discovered “that a greater part of the composition had seperated from the skins and left the seams of the boat exposed to the water and she leaked in such manner that she would not answer. I need not add that this circumstance mortifyed me not a little.”

Failure

I therefore relinquished all further hope of my favorite boat and ordered her to be sunk in the water, that the skins might become soft in order the better to take her in peices tomorrow and deposite the iron fraim at this place as it could probably be of no further service to us.

—Meriwether Lewis

Lewis’s mortification was a direct result of his wishful thinking that a mix of tallow, beeswax, and charcoal could substitute for pitch. This composition was fine for filling cracks in the dugout canoes, which—unlike the Experiment—were rigid, solid-hulled vessels. Inevitably, the iron boat flexed as its hide, bark, and wood reacted to water and the dry Montana air. As Gass succinctly observed, “The tallow and coal were found not to answer the purpose; for as soon as dry, it cracked and scaled off, and the water came through the skins.”[55]Ibid., Vol. 10, p. 110.

True to his nature, Lewis second-guessed himself about the iron boat’s failure. He blamed the sewing needles used, which had sharp edges that cut the skin. The way strips, or thongs (which he spelled “throngs”) filled the needle holes when the hides were wet, but as they dried, the holes expanded so that “the throng does not fill the holes as I expected tho’ I made them sew with a large throng for that purpose.”[56]Ibid., Vol. 4, pp. 354-355. The entry is for 3 July 1805. Two days later, Lewis noted that “the stitches begin to gape very much since she has begun to dry; I am now convinced this would not … Continue reading

Lewis also concluded that the boat might have stayed afloat had they left enough hair on the hides. He noted that the hair on some of the buffalo hides had not been burned off completely; these “leaked but little and the parts which were well covered with hair about 1/8th of an inch in length retained the composition perfectly and remained sound and dry.” If only he had covered the boat “with buffalo skins singed not quite as close” as the ones employed. Alternatively, “had I only singed my Elk skins in stead of shaving them I beleive the composition would have remained [in place] at least untill we could have reached the pine country . . . where we might have supplyed ourselves with the necessary pich or gum.”[57]Ibid., p.369.

Lewis was right to be concerned about the needle holes, and they might not have been a problem if he could have sealed them with pitch, a stickier and more elastic medium than his tallow-based substitute. This assumes, of course, that pitch sticks to leather as readily as it does to birch bark. If so, the best and simplest solution might have been to lay in a supply of pitch in advance of the corps’s departure from Fort Mandan. The captains could have set up their tar kiln there or even at Camp River Dubois, in Illinois. Instead, Lewis clung to the hopeful assumption that he would find pines at the Great Falls.

His assertions notwithstanding, it is doubtful that hair on the hides would have enabled the tallow to adhere to them for long under the rigorous conditions of river travel and the constant flexing from loading and unloading supplies and men. Buffalo hair may have retarded drying and kept the tallow pliant for a while, but probably sooner than later it would have hardened, cracked, separated, and peeled.

A larger issue is the difficulty inherent in making a waterproof covering of sewn hides with no practical knowledge of the subject. In the far north, Athabaskans and Inuits built seaworthy boats from oiled hides sewn together with small needles, using a technique that did not fully penetrate the skin.[58]Adney and Chapelle, p. 186. But these skilled craftsmen had generations to develop and refine their methods; Lewis had three weeks.

The Experiment’s failure left the captains in a bind about the baggage it was intended to carry. They decided to use the existing canoes to ferry its cargo several miles up the Missouri to an area of bottomland they knew to be well timbered with large cottonwoods—raw material for two more dugouts. Clark led 10 axemen overland to start the boat-building job while Lewis and six others stayed behind to take apart the Experiment and cache its disassembled frame. The task took only a couple of hours. When they finished, Lewis went off to nurse his regrets at the end of a fishing line.[59]Moulton, Vol. 4, p. 371.

Experience the Lewis and Clark Trail

The Lewis and Clark Trail Experience—our sister site at lewisandclark.travel—connects the world to people and places on the Lewis and Clark Trail.

Plan a trip related to The Iron-framed Boat:

- Harpers Ferry National Historic Park

- Harpers Ferry to Brownsville (Inspiration Trip)

Notes

| ↑1 | Mark W. Jordan, “Meriwether Lewis’s Ingenious Iron Boat,” We Proceeded On, May 2003, Volume 29, No. 2, the quarterly journal of the Lewis and Clark Trail Heritage Foundation. The original article is provided at lewisandclark.org/wpo/pdf/vol29no2.pdf#page=26. |

|---|---|

| ↑2 | Donald Jackson, ed., Letters of the Lewis and Clark Expedition with Related Documents, 1783-1854, 2 volumes (Urbana: University of Illinois Press, 1978), Vol. 1, p. 39. |

| ↑3 | Ibid., p. 73. |

| ↑4 | Gary Moulton, ed., The Journals of the Lewis and Clark Expedition, 13 volumes (Lincoln: University of Nebraska Press, 1984-2001), Vol. 4, p. 149. All quotations or references to journal entries in the ensuing text are from Moulton, by date, unless otherwise indicated. |

| ↑5 | Moulton, Vol. 10, p. 110. |

| ↑6 | For more on this, see Donald W. Rose, “Captain Lewis’s Iron Boat: ‘The Experiment,’” We Proceeded On, May 1984. |

| ↑7 | Letter of 20 April 1803, to Jefferson. Jackson, p. 40. |

| ↑8 | See also the reference in his inventory. Jackson, p. 73. |

| ↑9 | For more on the indispensable use of the canoe in the exploration of North America, see Peter C. Newman, Caesars of the Wilderness (Ontario: Viking, 1987); and David Lavender, Winner Take All (New York: McGraw-Hill, 1977). |

| ↑10 | Richard Dillon, Meriwether Lewis: A Biography (New York: Coward-McCann, 1965), p. 25. Kenneth G. Roberts and Phillip Shackelton, The Canoe (Toronto: Macmillan of Canada, 1983), p. 198. |

| ↑11 | Moulton, Vol. 4, p. 356. |

| ↑12 | Edwin Tappen Adney and Howard I. Chapelle, The Bark Canoes and Skin Boats of North America (Washington, D.C.: Smithsonian Institution Press, 1983), p. 138. |

| ↑13 | Illustrations adapted from Edwin Tappen Adney, The Bark Canoes and Skin Boats of North America (1964); text from Adney and John A. McPhee, The Survival of the Bark Canoe (1975). |

| ↑14 | Samuel de Champlain, Voyages in New France, as quoted in Roberts and Shackelton, p. 171. |

| ↑15 | Adney and Chapelle, p. 13; Roberts and Shackelton, p. 197. |

| ↑16 | In areas where birch did not grow, natives covered their canoes with the bark of elm, spruce, hickory, or basswood—but these were less durable substitutes. Some builders—notably the Inuit and Athabaskans, who lived north of tree line—covered their boats with skins. Adney and Chapelle, pp. 175-211. |

| ↑17 | The following description of bark-canoe construction is based on Roberts and Shackelton, pp. 156-163; Adney and Chapelle, pp. 145-150; and John McPhee, The Survival of the Bark Canoe (New York: Farrar, Straus and Giroux, 1975), pp. 47-54. |

| ↑18 | Eric Morse, Fur Trade Canoe Routes of Canada, Then and Now (Toronto: University of Toronto Press, 1969), p. 23. Moulton (Vol. 4, p. 346, fn. 3) states that Lewis also used the word “waytape,” a possible corruption of wattape. Compare this to Lewis’s use of the term “way strips” in his journal. |

| ↑19 | Moulton, Vol. 4, p. 369 (entry for July 9, 1805). |

| ↑20 | Jackson, p. 39. |

| ↑21 | Ibid. Lewis uses “stern” to refer to the after end of the canoe. A canoe, of course, is symmetrical, so that either end can be the stem (fore end, or bow) or stern, depending on the direction the paddlers are facing. It is clear from the letter’s context that both ends of the iron boat, like those of a fur-trade canoe, had the same shape and dimensions. |

| ↑22 | Jackson, p. 39. |

| ↑23 | Moulton, Vol. 11, p. 217. |

| ↑24 | This number can also be confirmed by the section lengths recorded by Lewis. Multiplying 4 feet 6 inches (the length of one center section) by six yields 27 feet, which subtracted from 36 feet 4 1/2 inches (the length of the assembled boat as measured at the Upper Portage Camp) yields 9 feet 4 1/2 inches (the total length of the stem sections), which divided by two equals 4 feet 8 inches and change—a figure very close to 4 feet 9 inches, the length of a stem section derived by adding 1 foot 2 inches (“Length of Keel from junction of section to commencement of curve”) and 3 feet 7 inches (“Length of curve”). |

| ↑25 | Jackson, p. 73. |

| ↑26 | Ibid., p. 39. |

| ↑27 | Compare this result with the weight assigned to the Experiment in other secondary sources. On page 31 of Lewis and Clark: Historic Places Associated with Their Transcontinental Exploration (Washington, D.C.: U.S. Department of the Interior, 1975), by Roy E. Appleman, the author states, “the frame when finished weighed 44 pounds.” This figure apparently results from combining the weight of the two test sections. On page 86 of Undaunted Courage: Meriwether Lewis, Thomas Jefferson, and the Opening of the American West (New York: Simon & Schuster, 1996), Stephen E. Ambrose makes the same mistake. On page 38 of Richard Dillon’s Meriwether Lewis, the author states that the frame, “a mere 99 pounds of metal, would make child’s play of portaging.” Dillon’s source is Lewis’s letter of 20 April 1803, to Jefferson, but the figure of 99 pounds refers to the full weight (iron, wood, and hides) of the two test sections. David Lavender makes the same error on page 41 of The Way to the Western Sea: Lewis and Clark across the Continent (New York: Harper & Row, 1988). |

| ↑28 | Jackson, p. 40. |

| ↑29 | Moulton, Vol. 4, p. 356. The actual field materials assembled at the Upper Portage Camp were probably heavier than those Lewis used in making his estimates at Harpers Ferry. |

| ↑30 | See Roberts and Shackelton, p. 200. Weight would vary based on length and width. |

| ↑31 | Ibid., p. 204. |

| ↑32 | Jackson, pp. 39-40. Both Appleman (p. 31) and Dillon (p. 38) mistake the Harpers Ferry calculation for the total burden of the canoe, asserting that the Experiment could carry only 1,770 pounds. Ambrose (p. 86) makes the same error. As with all the information recorded at Harpers Ferry, the numbers refer only to the two test sections, not the entire canoe. |

| ↑33 | Lewis’s exact wording is, “I am confident that in cases of emergency they would be competent to 150 lbs.” If each of the eight sections could carry 150 additional pounds, it would increase the Experiment’s capacity by 1,200 pounds. Added to 7,220 pounds, this figure gives a total burden of 8,420 pounds. If he was referring to the burden of the combined sections (150 pounds, or 75 pounds each), then the additional burden would amount to 600 pounds, for a total burden of 7,820 pounds. |

| ↑34 | A pirogue is a wooden boat, often in the shape of a canoe. Lewis used the terms pirogue and canoe interchangeably when referring to the expedition’s two pirogues. (Moulton, Vol. 2, p. 71, fn. 1.) The expedition’s two pirogues were probably made from planking, while its dugout canoes were hewed from logs. The pirogues were longer than the canoes and fitted with removable masts for sailing when the wind was right. |

| ↑35 | The “screws” used for assembling the frame had threads that matched the grooved holes drilled into the frame. Whitehouse is quite clear about this when he states that the iron boat had “holes & screws to fit them.” (Moulton, Vol. 11, p. 207.) Depending on the head and whether the shaft was tapered or cylindrical, what Lewis called a screw might better be thought of as a bolt. Whether screws or bolts, it’s not clear how these devices were actually driven into their sockets; in his journal entry for 21 June 1805, Lewis refers to “the necessary tools” to assemble the frame, but he is silent on whether they were screwdrivers or wrenches (neither of which are listed in his equipment inventory). |

| ↑36 | Ibid., p. 330. Gass’s entry of 23 June 1805 (Moulton, Vol. 10, p. 105) records the same measurements. |

| ↑37 | This can be inferred from Lewis’s journal entry for July 2, eight days after the measurements were taken: “myself and all other hands engaged in putting the boat together which we accomplished in about 3 hours.” |

| ↑38 | On 27 June 1805, Lewis recorded that “Shields and Gass continued the operation of shaving and fiting the horizontall bars of wood in the sections of the boat.” Patrick Gass—the corps’s resident carpenter—provides slightly more illumination in his journal entry for 23 June: “The iron boat is to be covered with skins and requires a quantity of thin shaved strips of wood for lining.” |

| ↑39 | Originally, Lewis probably planned to add only a few wooden horizontal bars because he intended to use large sheets of bark as the primary support, or lining, for the skin covering. In the experiments at Harpers Ferry, he used substantially more bark than wood, as can be seen from the weights of each material listed in his letter of 20 April 1803, to Jefferson (bark, 21 and 25 pounds; wood 10 and 12 pounds). In Montana, good bark was not available, so more wood was necessary to support the skin covering. |

| ↑40 | Entry for 27 June 1805. |

| ↑41 | On p. 41 of The Way to the Western Sea, Lavender states that a lattice of sticks supported the covering. If by “lattice” he meant the classical use of wood sticks laid over each other, such as is used in the bull or buffalo boat, he cannot be correct. Lattice would have been impractical in any event, and even more so with the poor wood that the builders had to use in the field. The sticks were shaved to make them flat. Flat horizontal bars provide the only suitable support for the skin and bark. |

| ↑42 | Moulton, Vol. 4, p. 337. Earlier journal entries note that Gass and Shields searched for bark as well as timber. See, for example, Moulton, Vol. 4, pp. 331 and 333. Lewis recorded that on 26 June 1805, “they brought some bark principally of the Cottonwood which I found was too brittle and soft for the purpose; for this article I find my only dependence is the sweet willow which has a tough & strong bark.” On July 3 the men were still busy “cuting and fitting bark for lining.” |

| ↑43 | In his entry for 30 June 1805, Lewis refers to this soaking process as necessary to “toughen the bark.” The context suggests that his purpose was to render the bark flexible so it could be flattened without breaking. |

| ↑44 | Lewis, July 1: “Gas[s] I set at work to make the way strips out of some willow limbs which tho’ indifferent were the best which could be obtained.” Moulton suggests that “way strips” were perhaps similar “to white spruce roots or bark strips used to fasten together birch-bark canoes.” (Vol. 4, p. 346, fn. 3.) |

| ↑45 | Moulton, Vol. 4, p.149. |

| ↑46 | Ibid., p. 261. |

| ↑47 | Jackson, pp. 71 and 72. Lewis’s inventory list included six saddler’s needles plus 24 gross of needles for Indian presents. |

| ↑48 | Moulton, Vol. 4, p. 338. |

| ↑49 | Lewis makes it reasonably clear that the sewing of the hides was done on a section-by-section basis. See Moulton, Vol. 4, pp. 344, 349. |

| ↑50 | Ibid., pp. 349, 351, and 363. In his journal entry for 21 June 1805, Whitehouse states that the iron boat “had screws to fasten the hides or skins that covered the bottom & sides.” (Moulton, Vol. 11, p. 207.) I think he is almost certainly wrong about this. As mentioned in note 33, there were certainly holes in the iron bars to receive the screws; but I believe that the frame also had lash holes for attaching the hides and that Whitehouse mistook these for screw holes. Whitehouse made this statement two days before the frame was assembled and 10 days before they began attaching the hides, and he never mentioned it again. More significantly, Lewis never stated that screws were used for attaching the hides to the frame. Nor did Gass. On the other hand, it is possible that the iron frame included not just single gunwale bars but (like a bark canoe) inwale and outwale bars joined by screws or bolts, with the hide sandwiched between them. |

| ↑51 | Entry of 24 June 1805. Moulton, Vol. 4, p. 330. Clark on 3 July 1805 noted that the men were “burning tar of the drift pine.” |

| ↑52 | Lewis, 21 June: “I readily perceive several difficulties in preparing the leather boat . . . above all that of pitch to pay her seams, a deficiency that I really know not how to surmount unless it be by means of tallow and pounded charcoal which mixture has answered a very good purpose on our wooden canoes heretofore.” |

| ↑53 | Gass states that the boat was launched in the “forenoon.” (Moulton, Vol. 10, p. 110.) |

| ↑54 | Moulton, Vol. 4, p. 368; Vol. 10, p. 110; and Vol. 11, p. 221. Whitehouse recorded that “the iron boat leaked so much, that we did not put any load into her.” (Moulton, Vol. 11, p. 222.) |

| ↑55 | Ibid., Vol. 10, p. 110. |

| ↑56 | Ibid., Vol. 4, pp. 354-355. The entry is for 3 July 1805. Two days later, Lewis noted that “the stitches begin to gape very much since she has begun to dry; I am now convinced this would not have been the case had the skins been sewed with a sharp point only and the leather not cut with the edges of a sharp nedle.” |

| ↑57 | Ibid., p.369. |

| ↑58 | Adney and Chapelle, p. 186. |

| ↑59 | Moulton, Vol. 4, p. 371. |